Online Store of Technical Associates of Charlotte, P.C.

Top Vibration Training Provider in the World

Categories

Low-Speed Machines

$79.00

1

Save this product for later

Low-Speed Machines

Product Details

Description:

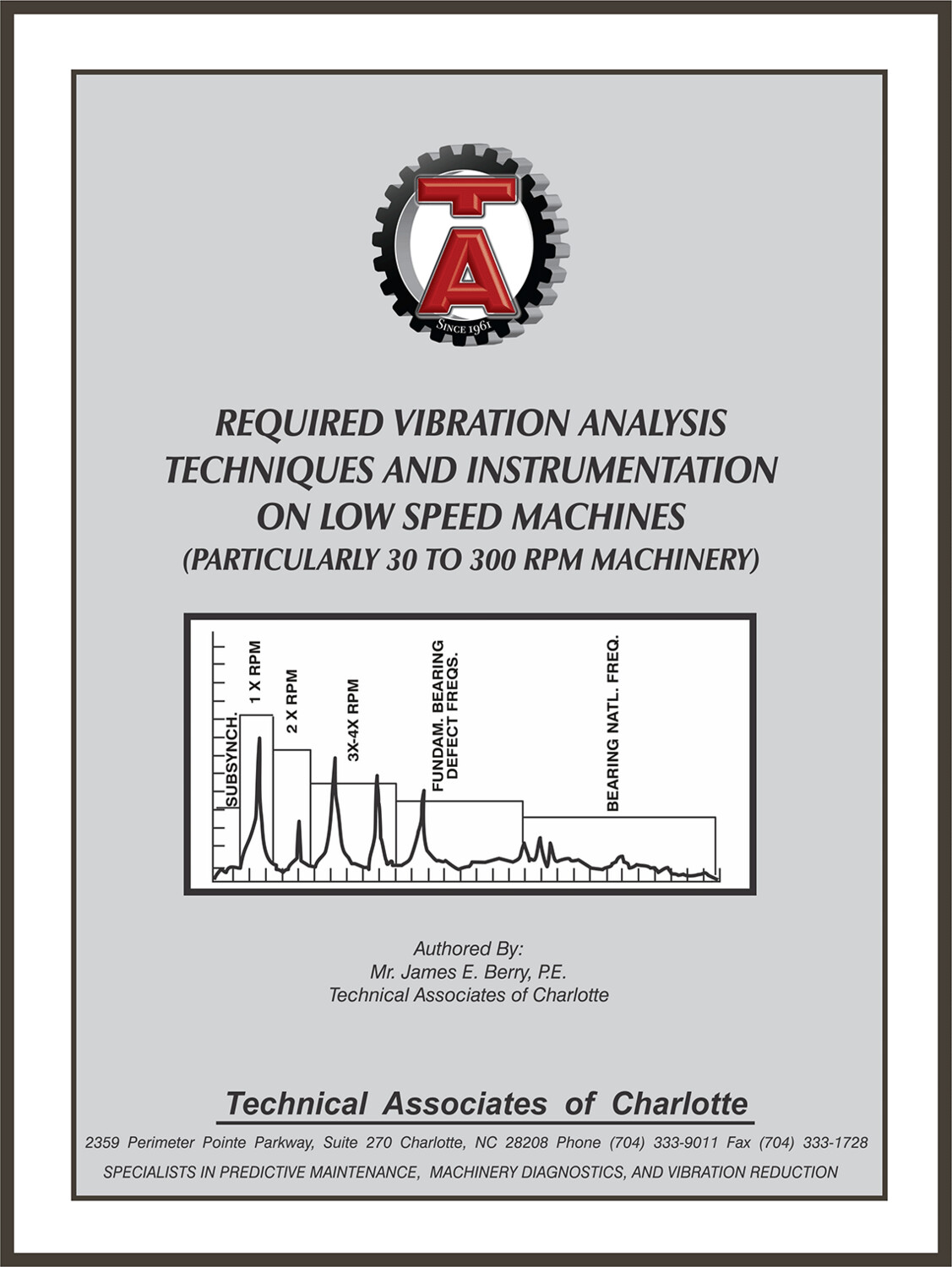

A Technical Paper on Required Vibration Analysis Techniques & Instrumentation on Low-Speed Machines (particularly 20-300 RPM machinery) (111 page booklet)

Highlights:

- This comprehensive paper is based on many years of research and field experience on this unique class of machines.

- This paper extensively covers the special techniques which must be employed on machines that may operate at speeds of only 20 to 100 RPM (plus shows how numerous problems can be detected even those operating below 20 RPM).

- Next, the paper discusses in detail the requirements of both instruments and transducers which must be employed if successful analysis of low-speed machines is to be performed.

- It openly discusses what difficulties will be encountered and makes strong recommendations on what type of transducers and instruments will have to be used.

- It also discusses the optimum vibration parameter which should be used to analyze low-speed machines when using both spectral analysis and time waveform analysis.

- It then covers how one should successfully evaluate rolling element bearings on low-speed machines.

- Next, the paper discusses how one should specify both overall and spectral band alarms for such low-speed machines (it reveals how and why such alarm levels will be significantly lower than those on nominal speed machines operating at speeds of 600 to 3600 RPM).

- The paper closes with a number of real-world case histories which have been performed on low-speed machines, including both problem detection and correction.

Powered by Lightspeed

Display prices in:USD